During the entire process of solar power plant construction, the quality and construction safety of each process must be controlled. For ground power station projects, quality control of key nodes can effectively prevent production accidents, operational failures and engineering problems caused by construction quality.

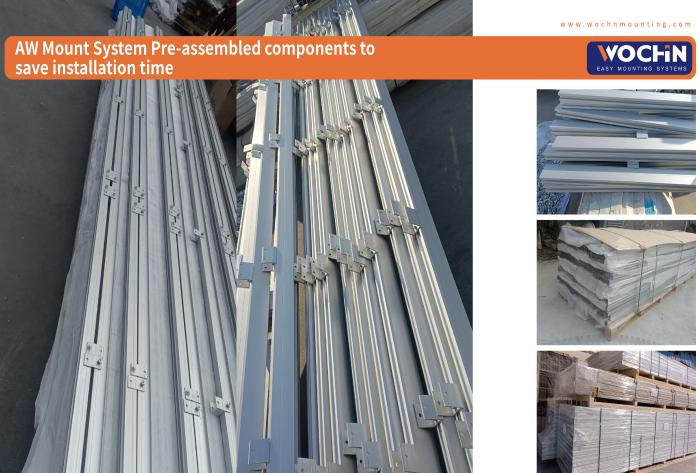

Material on-site acceptance

After all materials arrive at the site, count the quantity and check for damage. If there are missing parts or damage, take timely measures to avoid affecting the progress of the project. When loading and unloading large equipment, professional equipment is required for lifting and handling. Load and unload nearby according to the drawings to avoid a large amount of secondary pollution during later construction.

When unpacking the equipment, count the equipment drawings, documents, certificates, reports, etc. and save them as technical information and construction data files for future equipment commissioning.

Civil foundation construction

The quality of the foundation directly affects the installation of the photovoltaic area and the positioning of the photovoltaic modules. The foundation must use professional measuring instruments (such as theodolite) to control the horizontal positioning.

When pouring the foundation, the verticality and elevation of the foundation and each component should be strictly controlled. After the foundation is demolished, the foundation settlement should be re-measured to determine the foundation settlement and unqualified deviations, and deal with them in time to avoid multiple deviation accumulation and overall unqualified deviations.

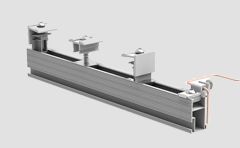

The installation of solar racking

The quality control of photovoltaic bracket installation is related to the quality of the components and the subsequent power generation benefits. In the initial design stage, the photovoltaic bracket design needs to be carried out according to the wind pressure, snow pressure, earthquake and other conditions of the project site, and the photovoltaic structure supplier shall provide relevant strength calculation data. The verticality of the columns and the horizontality of the beams and tracks should be ensured. The verticality and horizontality of a single array will affect the installation quality of the components. The components should be evenly stressed on the bracket to avoid cracking caused by uneven stress.

The solar bracket is equipped with a full set of fasteners (gaskets, spring washers), which are tightened to increase the friction of the bracket installation and prevent loosening due to vibration. During the installation process, the bracket is positioned and leveled during the tightening process. After the bracket is leveled, re-tighten it.

In addition, electrical equipment also bears the responsibility of transmitting the energy of the photovoltaic system. The safe and stable operation of electrical equipment depends on the quality of its installation. When installing equipment such as transformers, high-voltage cabinets, and AC cables, the horizontality and verticality of the equipment must be within the deviation range. After the equipment is installed, the corresponding withstand voltage and insulation tests should be carried out in a timely manner. The laying and grounding of cables should also be carried out by professionals in accordance with safety requirements.